Customized production

We are able to quickly respond to customer needs in the field of gaskets and industrial insulation. We are capable to transfer drawing documentation (dxf, dwg, pdf) directly to the plotter cuting machine.

Thanks to long-term partnerships with selected suppliers, we are able to work reliably and efficiently even on larger projects and supplies of insulation. We cooperate very closely with the company RUML Industry, which deals with CNC processing, sheet metal bending and the production of steel weldments.

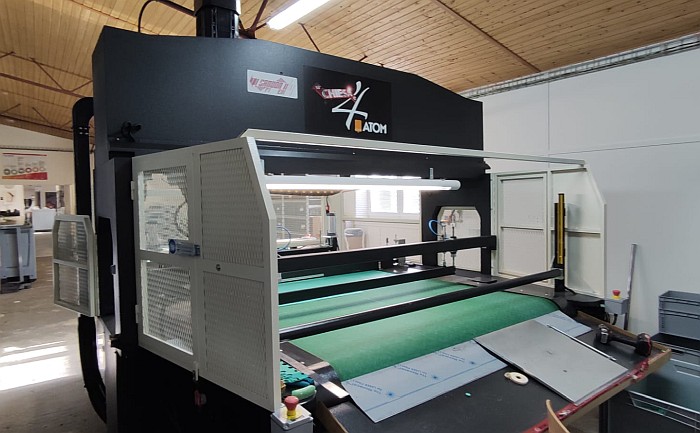

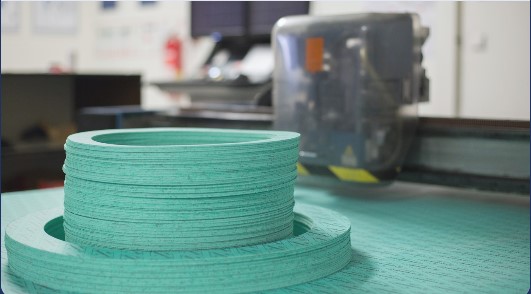

CNC cutting press

Highly effective gassket production in high series volume on CNC press Chiesa Sanson F1.

We produce large series of gaskets, cutouts, washers, etc. on a CNC press with a cutting force of 25 tons. Maximum material width (also in roll) 1600 mm. Processes materials up to 10 mm thick (microporous rubber up to 20 mm).

Go to non-binding inquiry

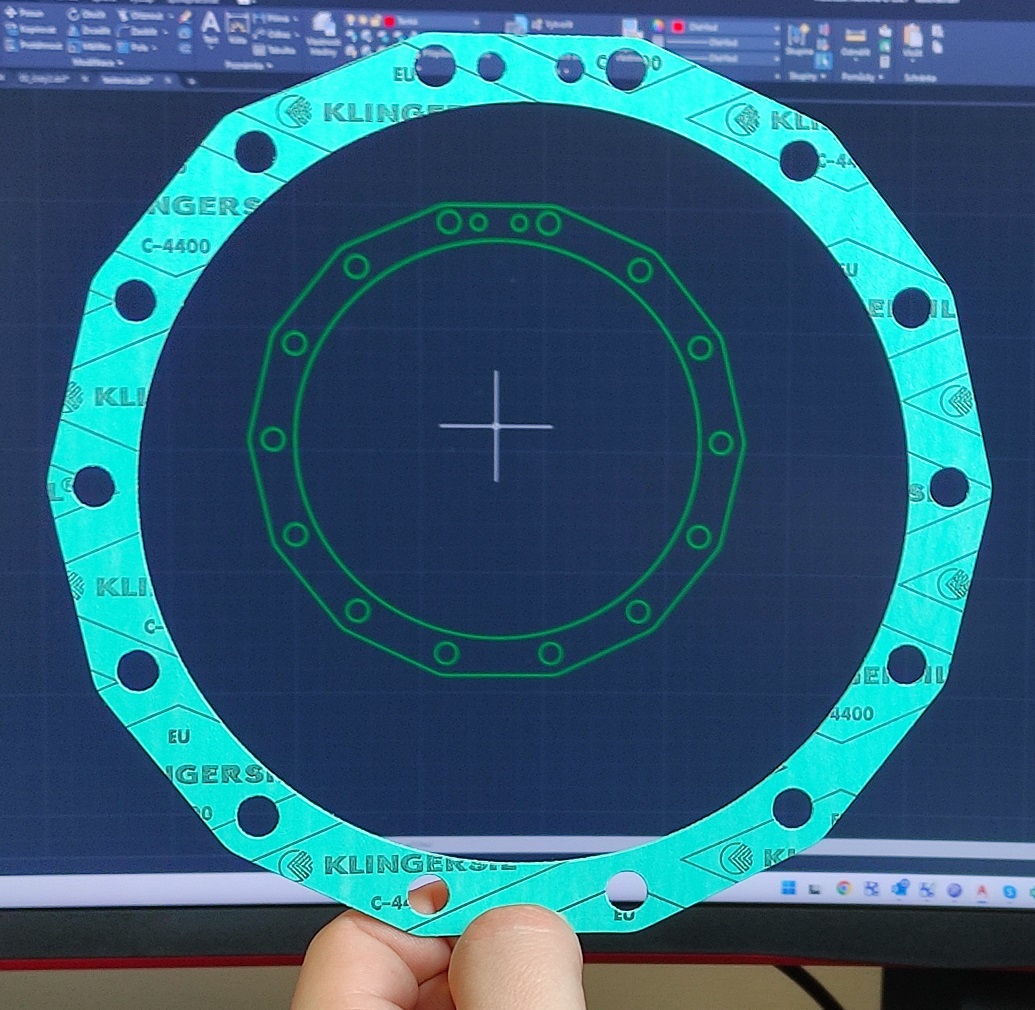

Cutting with a CNC plotter

Manufacture of customized industrial gaskets according to an individual drawing

We use a modern, high-speed and precise CNC plotters. Thanks to the beamers above the cutting surface, it is possible to precisely determine the cut-out in the material. We can cut almost any shape from soft materials up to 19 mm thickness.

Go to non-binding inquiry

Die-cutting on a press

Production of sealants in large series on hydraulic presses.

Die-cutting is carried out with the help of two hydraulic presses with a working pressure of 12 tons. The thickness of the die-cut seal or insulation can be up to 50 mm.

Go to non-binding inquiry

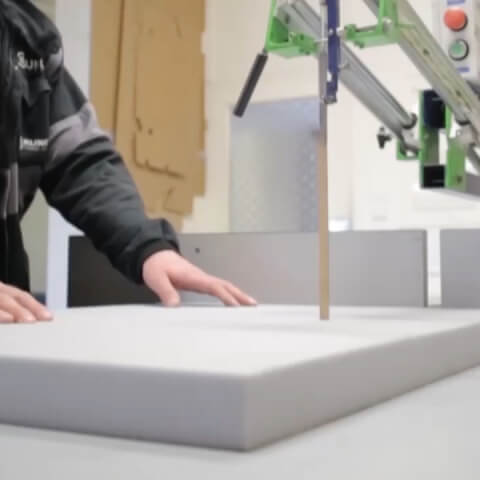

Cutting insulation on a saw

Production of finished cut-outs of industrial thermal and noise insulation.

For cutting harder insulation materials such as Hannotect, we use a specially designed saw that can cut materials in a vertical cut up to a thickness of 220 mm and in an skived cut up to a thickness of 160 mm.

Go to non-binding inquiry